standard brinell hardness test|brinell hardness chart pdf : mfg 1.1 This test method covers the determination of the Brinell hardness of metallic materials by the Brinell indentation hardness principle. This standard provides the . 2 dias atrás · NVIDIA GeForce RTX 20 系列显卡和 RTX 20 系列笔记本电脑均配备专用的光线追踪技术和 AI 核心。RTX 20 系列游戏性能相较上一代显卡提升高达 6 倍,并且具备实时光线追踪和 AI 的强大功能。

{plog:ftitle_list}

Resultado da 3 de jan. de 2024 · This feedback request email is a quick and efficient way to ask. Dear [Recipient's Name], I hope this email finds you well. I am writing to request your valuable feedback. As we continue to collaborate on various projects and tasks, I believe it is important to gather insights from our team .

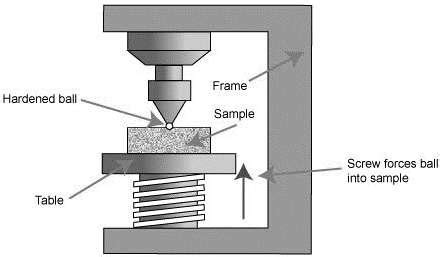

1.1 This test method covers the determination of the Brinell hardness of metallic materials by the Brinell indentation hardness principle. This standard provides the .This part of ISO 6506 specifies the method for the Brinell hardness test for metallic materials. It is applicable to both fixed location and portable hardness testing machines.When quoting a Brinell hardness number (BHN or more commonly HB), the conditions of the test used to obtain the number must be specified. The standard format for specifying tests can be seen in the example "HBW 10/3000". "HBW" means that a tungsten carbide (from the chemical symbol for tungsten or from the Spanish/Swedish/German name for tungsten, "Wolfram") ball indenter was used, as opposed to "HBS", which means a hardened steel ball. The "10" is the ba.According to ISO 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the Brinell hardness (HBW).

The Brinell hardness test identifies the indentation hardness of a desired material. Guidelines for Brinell testing machines and the procedures for performing Brinell hardness .As the Brinell hardness test (HBW) indentation leaves a relatively large impression, the Brinell hardness test is better suited to larger samples with a coarse or inhomogeneous grain structure, such as castings and forgings. .

Abstract. ISO 6506-1:2014 specifies the method for the Brinell hardness test for metallic materials. It is applicable to both fixed location and portable hardness testing machines.The Brinell hardness testing standard is ASTM E10. For both Vickers and Brinell hardness testing, it is common to use reference tables to give the value of hardness for a given .

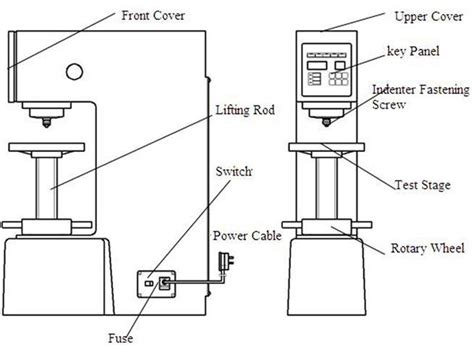

brinell hardness testing machine diagram

The Brinell hardness test was developed by the American Henry Brinell, who created the first tester in 1873. This is a widely accepted method in the field. The ASTM’s Brinell hardness test standard is used by alloy and metal suppliers and users, and it’s a basic requirement for all hardness testing equipment. As for the ASTM E10-23 standard, there is a heavy focus on the background of and actions taken throughout the Brinell hardness test procedure. This includes requirements and thorough detail on measuring the indentation, verifying the testing machines, converting to other hardness values, and preparing a test report.The typical relationship between indentation diameter and HB is provided in Table 2.The standard ball for Brinell testing is 10 mm (±0.005 mm) in diameter and should have a minimum hardness of 850 HV.When balls of smaller size are used, the load as well as the ball size should be specified along with the test result.

The Brinell hardness testing standard is ASTM E10. For both Vickers and Brinell hardness testing, it is common to use reference tables to give the value of hardness for a given indentation size and load, instead of making a calculation each time. 9.11.3 Rockwell hardness test.

As the Brinell hardness test (HBW) indentation leaves a relatively large impression, the Brinell hardness test is better suited to larger samples with a coarse or inhomogeneous grain structure, such as castings and forgings. . Wolfram carbide (= tungsten carbide) underlines that newer Brinell standards call for the use of tungsten carbide .Indian Standard METHOD FOR BRINELL HARDNESS TEST FOR METALLIC MATERIALS ( Third Revision) 1 Scope This part of ISO 6506 specifies the method for the Brinell hardness test for metallic materials and is applicable up to the limit of 650 HBW. For specific materials and/or products, particular International Standards exist (i.e. ISO 4498-l).A chart is then used to convert the averaged diameter measurement to a Brinell hardness number. Test forces range from 500 to 3000 kgf. A Brinell hardness result measures the permanent width of indentation produced by a carbide indenter applied to a test specimen at a given load, for a given length of time.Standards of Brinell Hardness Testing. When it comes to Brinell hardness testing, adherence to standardized procedures and specifications is crucial to ensure accurate and reliable results. The American Society for Testing and Materials (ASTM) has established comprehensive standards for Brinell hardness testing, providing guidelines and .

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .The combinations of indenters and test forces define the Brinell hardness scales. The standard Brinell hardness scales and test forces correspond to force-diameter ratios of 1, 1.25, 2.5, 5, 10 and 30. Standards: DIN EN ISO 6506 / ASTM E10 Brinell Methods 2.2 Method Indenter Load F kg Load F N Load Factor 0.102 x F/D2 Hardness Range HBW*

Standards of Brinell Hardness Testing. When it comes to Brinell hardness testing, adherence to standardized procedures and specifications is crucial to ensure accurate and reliable results. The American Society for Testing and Materials (ASTM) has established comprehensive standards for Brinell hardness testing, providing guidelines and . Rockwell Hardness Standard Test. The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by measuring the difference in depth of .The standard ball for ASTM E10 Brinell hardness testing shall be 10,000 mm in diameter, with a deviation from this value of no more than 0.005 mm in any diameter. Result: The Brinell hardness number (BHN) is a crucial output of the ASTM E10 .

Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. . The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1 .

The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. . Add standard and customized parametric components - like flange beams, lumbers, piping, stairs and more .

Standard Test Method for Brinell Hardness of Metallic Materials 1 This standard is issued under the ®xed designation E10; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript . The standard-compliant specification of Brinell hardness consists of the hardness value (HBW), the ball diameter (in millimeters), the test force (in kiloponds) and the application time (in seconds). These values are given without units and separated by slashes.4.1 The Brinell hardness test is an empirical indentation hardness test. Brinell hardness tests provide useful information . 5.2.1 The standard ball for Brinell hardness testing shall be 10.000 mm in diameter with a deviation from this value of not more than 0.005 mm in any diameter. The ball shall be polished

https://engineers.academy/This video outlines how a Brinell hardness test is conducted, as well as explaining how to calculate a value for the Brinell hardne.Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table . Brinell Hardness: Rockwell Hardness: Tensile Strength (Approximate) Psi: Tungsten Carbide Ball 3000 KG: . Engineering Standards Finishing and Plating Friction Formulas Apps Lubrication Data Apps Machine Design Apps Manufacturing Processes

brinell hardness tester diagram

When is the Brinell hardness test used? Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being tested.

The standard dimensions of the Brinell hardness test blocks are as follows: Square Brinell Hardness Test Blocks Length: 152.40mm (6") Depth: 50.90mm (~2") Thickness: 6.85mm (~0.25") Request quote to get your consumables price catalogue.Wilson Brinell hardness test blocks set the standard for the industry and are made from the highest quality material to insure the most uniform and repeatable Brinell test blocks available. A comprehensive variety of scales and blocks are available to meet the wide ranges and hardness scales associated with Rockwell®, Brinell, Knoop and .Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; . Hardness testing standards have been set by various organisations such as The American Society for Testing and Materials (ASTM) and The International Organisation for Standardisation (ISO), prescribing specific .

Brinell Hardness Test Equations, Calculators and Review . The standard format for specifying tests can be seen in the example "HBW 10/3000". "HBW" means that a tungsten carbide (from the chemical symbol for tungsten) ball indenter was used, as opposed to "HBS", which means a hardened steel ball. The "10" is the ball diameter in millimeters. 1.3 The portable hardness testers covered by this test method are verified only by the indirect verification method. Although the portable hardness testers are designed to employ the same test conditions as those defined in the standard test methods, the forces applied by the portable Rockwell and Brinell testers and the depth measuring systems of the portable .

refractometer for sorbet

brinell hardness test pdf

Totally.Killer.2023.1080p.WEBRip.1400MB.DD5.1.x264-GalaxyRG. Seeders : 307. Leechers : 20. Downloads : 1609. Size : 1.4 GB. Uploaded : 06 Oct, 2023. Uploader : .

standard brinell hardness test|brinell hardness chart pdf